VRX Silica Ltd higher on grant of Mining Lease for Muchea

Oct 29, 2020#0183;#32;VRX Silica Ltd has been granted a Mining Lease for the Muchea Silica Sand Project, which is around 50 kilometres north of Perth, Western Australia.. The Mining

WhatsApp)

WhatsApp)

Oct 29, 2020#0183;#32;VRX Silica Ltd has been granted a Mining Lease for the Muchea Silica Sand Project, which is around 50 kilometres north of Perth, Western Australia.. The Mining

Silica sand deposits are most commonly surfacemined in open pit operations, but dredging and underground mining are also employed. Extracted ore undergoes considerable processing to increase the silica content by reducing impurities.

Apr 13, 2017#0183;#32;Demand for industrial silica is expected to grow worldwide, in excess of percent over the next several years. Sand sales for construction and fracking purposes will grow by much larger percentages. * Frac Sand in the Fracking sands are primarily mined in an open pit process.

Oct 29, 2020#0183;#32;Special Report: VRX has a clear pathway to develop its high grade Muchea silica sand project in Western Australia after securing the critical mining lease. Muchea is the most attractive of the companys three silica sand projects thanks to its higher quality sand that makes it especially suitable for the ultraclear glass used in hightech applications such as solar panels, fibreoptics, LCD

Silica sand mining. Photo: Mary Kenosian. Southeastern and south central Minnesota and southwestern Wisconsin have extensive deposits of sand that meets the specifications required for hydraulic fracturing, or fracking, a drilling method used for natural gas and oil wells. Mining of these deposits has been occurring in the region for many years, however recent years have seen an increase of activity.

There is interest in developing new industrial silica sand mines in Minnesota due to a rapid expansion of shale oil and gas development over the past decade and the use of the hydraulic fracturing extraction method. Silica sand mining has been a divisive topic in Southern Minnesota.

Silica sand, also known as quartz sand, white sand, or industrial sand, is made up of two main elements: silica and oxygen. Specifically, silica sand is made up of silicon dioxide (SiO2). The most common form of SiO2 is quartz a chemically inert and relatively hard mineral.

To quantify risk of ambient exposure to airborne particulates around industrial silica sand operations, this study used EPAcertified federal reference method monitors to measure the levels of PM 10 and PM particulate matter. The monitoring sites were chosen based upon EPA siting criteria, dichotomous samplers were calibrated before and after sampling, and pre and postweight filter

Metallurgical ContentThe Silica Sand FlowsheetSANDSTONE DEPOSITSOPEN SAND PIT (Dry)OPEN SAND PIT (Wet)PRIMARY CLASSIFICATIONATTRITION SCRUBBINGSECONDARY CLASSIFICATIONCONDITIONING AND FLOTATIONFINAL DESLIMINGDRYING AND DRY GRINDINGSummary of the Silica Sand Processing Plant EquipmentA Flowsheet for Beneficiation of Silica

The specifications for each use vary, but silica resources for most uses are abundant. In almost all cases, silica mining uses open pit or dredging mining methods with standard mining equipment. Except for temporarily disturbing the immediate area while mining operations are active, sand and gravel mining usually has limited environmental impact.

Mar 13, 2019#0183;#32;Some frac sand mines (mines that extract silica sand to be used for hydraulic fracturing) use products called flocculants to remove silt and clay in the sand washing process. These products are generally considered to be environmentally safe; however, they often contain low concentrations of chemicals (acrylamide and DADMAC) that are of potential concern.

method of separation of chromite sand from silica sand Nov 23, 2012 #183; Silica sand processing plant manufacturer, silica sand washing plant. chromite ore crusher machine; . Washing and size classification is the simplest and economic method of cleaning silica sand. .sand making and separation machine . #187;More detailed. /5()Get Price

method to make purity quartz sand to 99 9. method to make purity quartz sand to 999. method to make purity quartz sand to 999. Hot Searchs. Silica Silicon Dioxide SiO2 AZoM 13 Dec 2001Silica occurs commonly in nature as sandstone silica sand or quartziteA high purity grade of silica fused silica which is around 994999 SiO2 isFlux sand for iron and steel making gt;90SiO2

Silica Mining In almost all cases, silica mining uses open pit or dredging mining methods with standard mining equipment. Except for temporarily disturbing the immediate area while mining operations are active, sand and gravel mining usually has limited environmental impact.

Relation to Mining. In almost all cases, silica mining uses open pit or dredging mining methods with standard mining equipment. Except for temporarily disturbing the immediate area while mining operations are active, sand and gravel mining usually has limited environmental impact. Uses

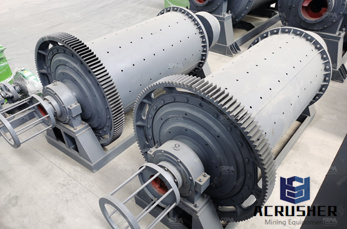

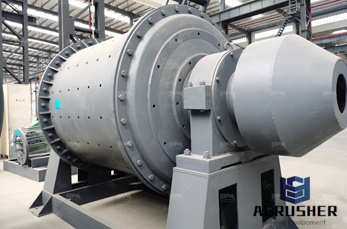

Silica Mining | Processing Equipment | Flow Chart | Cases

Over the past decade, a sharp increase in demand for sili ca sand corresponded with a rapid expansion of shale oil and gas development. An extraction method called hy draulic fracturing is used to access oil and gas from shale and limestone bedrock which can require approximately 10,000 tons of

The free silica content is calculated by comparing the major quartz peak intensities of the sample with that of a standard lithium fluoride (LiF) mixture. Respirable Silica (Free Quartz) On Air Filter Cartridges. In the workplace, respirable silica is loaded onto a 25 mm, #181;m pore size silver membrane filter.

The largest user of Saskatchewan''s silica sand is Hudson Bay mining and smelting co. ltd. In Flin Flon, an estimated six million tones of metallurgical sand have been used by the company since 1933. The Red Deer River deposits are being developed using onsite screening and washing facilities for the production of white sand for the golf course

Silica Sand Mining introduces. Foundry silica sand is the quartz as the main mineral composition, particle size of mm to mm refractory particles, according to the mining and processing methods of different can be divided into artificial silica sand and sand washing, sand washing, selection of natural silica sand such as sand (flotation).

Sand Mining Method Statements . Prompt : Caesar is a famous mining equipment manufacturer wellknown both at home and abroad, DNR''s role in silica sand projects and general information about silica sand mining in Minnesota. Strip Mining Local History Index. Strip Mining Subjects: Strip Mining; Record 671446 Record 664283 Record 663461

Jun 13, 2014#0183;#32;Different mining methods (mechanical or manual) are adopted for the extraction of sand from these sources under dry (above water table) and/or wet (below water table) conditions. This chapter describes briefly the different sources, methods and hydrogeological bearings of sand and gravel extraction processes in river ecosystems.

Over the past decade, a sharp increase in demand for sili ca sand corresponded with a rapid expansion of shale oil and gas development. An extraction method called hy draulic fracturing is used to access oil and gas from shale and limestone bedrock which can require approximately 10,000 tons

Sand mining has led to deepening and widening of the Lake Poyang channel, the largest freshwater lake in China and a biodiversity reserve of exceptional importance, and to an increase in water discharge into the Yangtze River. This may have influenced the lowering of the lakes water levels, which reached a historically low level in 2008.

WhatsApp)

WhatsApp)