(PDF) DECREASE PRODUCTION COSTS IN A COTTON

PDF | On Jan 1, 2013, Ionel Barbu published DECREASE PRODUCTION COSTS IN A COTTON SPINNING MILL BY AGGREGATISATION MACHINES | Find, read and cite all

WhatsApp)

WhatsApp)

PDF | On Jan 1, 2013, Ionel Barbu published DECREASE PRODUCTION COSTS IN A COTTON SPINNING MILL BY AGGREGATISATION MACHINES | Find, read and cite all

Cost reduction strategies in manufacturing Cut down material costs. One of the simplest ways to reduce manufacturing overhead costs in by cutting down the material costs. This can be achieved by tweaking product designs and effectively utilizing all the resources available at hand.

Power cost relative to sales turnover generally increased with the average count from about % in 20s to 30s to around 18% in finer counts above 70s. Power cost per unit was Rs and

Normally, spinning mills can maintain the spindle utilisation up to 98% consistently. Therefore, Table 4 implies that the mills must take all efforts towards maintaining the power cost at optimum level. Conservation of energy is one of the means to reduce the power cost to some extent.

Dec 08, 2020#0183;#32;There are various energy saving methods that exist in every spinning mills. Here, some important ways will be discussed that can reduce power consumption significantly. All main motor and suction motor of ring frame must be included inverter drive that will reduce power up to 30%. Proper lubrication, good quality bearing, and driving belt can reduce power.

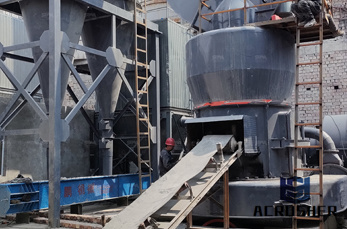

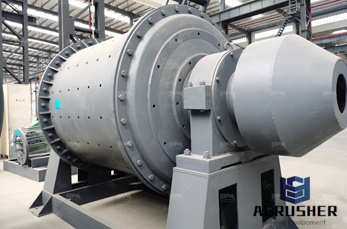

Raymond Mill. Adopting many advantages from various mills, and the ideal substitute of the Raymond Mill. READ MORE. Vertical Roller Mill. Automatic control system makes remote control, low noise, and integrate sealing device stop dust spill and pollute the environment. cost reduction in spinning mills .

Dec 13, 2020#0183;#32;Timing belts, Servo drive or Variable frequency drive, modified circuits, etc. have been developed and successfully implemented in the spinning industry to reduce power consumption. Humidification plant also contains a large scope of improvement by regular checking of compressed air pipeline, supply air and return air maintenance.

#0183;#32;Power Spent on Compressor is now controlled to % Power spent on plant is controlled to 8% Utilising all Machines as per Spin plan Factor 60s C 67s C No of RF 7 3 gps 73 59 Sx Reqd Drg Reqd Combers Cards Depending on the machines available, we should plan a required running shifts pattern for each count in will save energy as

Cost Reduction And Control In Spinning Mills. manufactured exports for lowincome countries that can exploit their labour cost advantages and fill emerging niches and meet buyer demandshere are also dynamic effects of tc industries and these dynamic effects are greater, the more linkages have been built up between the garment industry and local textile suppliers....

How To Reduce Power Cost In Spinning Mills. Cost Reduction In Spinning Mills 8 183 cost reduction in spinning mills manganese crusher search cost reduction in spinning mills to find your need zenith mining and construction machinery is a global manufacturer and supplier we supply full crushing

Cutting energy losses reflects lean manufacturing practices and is one way the mill can reduce power costs. On off days, maintenance is like timely first aid to ageing machines.

How to reduce power cost in spinning mills. Nov 15, 2020#183; spinning mill machinery list | textile spinning mill machine names written by mozaffor hosen sunday, .It is the reduction of entangled mass of fibers of filmy web by working them between two closely

How To Reduce Power Cost In Spinning Mills. Cost reduction of spinning mill controlling the cost of production at optimum level is one of the for the spinning mills to compete successfully in the market. Hence,mills are expected to initiate suitable measures such as profitable productmix, higher productivity

How to improve productivity and control cost in a spinning mill Part . Dec 1, 2016 In fact, it increases the yarn cost by increasing the man power cost. They seemed they had understood my point. Can you suggest some of the measures to be taken to reduce the process variation, sir? Someone from the back row of the audience asked.

In case of modern textile machinery, with their rising cost, complications, and automation, the necessity of maintenance has become very machine plays a very important role in determining the productivity of the mill, quality of products, power consumption amp; so on. Hence, in spinning units, it is important that condition of major

Apr 21, 2009#0183;#32;In indonesia, most of the units use PLN power and some of the spinning mills use Gensets. A detailed costing has to be done to compare the cost per unit to decide, Whether to use the PLN power or to go in for Gensets. while working out the costing finance cost on investment, overhauling cost, running cost, efficiency of the machine should be considered for cost caluculation

Spinning mills in the Telegana State which has comprise 20 to 30 percent of the production cost, to reduce power tariff for spinning mills, Learn More cost reduction and control in spinning mills

#0183;#32;Power or energy is the most critical cost factory in the spinning mills. With recent hikes in gas and power prices, the spinning mills are suffering for productivity shortage. Increasing efficiency and eliminating wastage in spinning mill is the key to remain competitive. In modern spinning mills there is no scope to allow any energy loss.

Power consumption pattern in the spinning mill is shown in Figure 3. It shows that spinning is the major power consuming operation and uses % of total energy. The second largest use of energy (%) is in humidification plant.

WhatsApp)

WhatsApp)