Coal mill, gypsum mill, clay mill, etc. | Pfeiffer MPS mills

MPS vertical mill from Pfeiffer is the ideal allrounder. Grinding of coal, petcoke, clay, limestone, quicklime, gypsum, and many other materials.

WhatsApp)

WhatsApp)

MPS vertical mill from Pfeiffer is the ideal allrounder. Grinding of coal, petcoke, clay, limestone, quicklime, gypsum, and many other materials.

Grinding of a high volatile bituminous coal was performed in three comminution devices: Raymond Mill, Rolls Crusher and Ball Mill. The pulverised samples were sieved to obtain four particle size fractions and temperatureprogrammed combustion (TPC) was used for the evaluation of their combustion behaviour.

TEMPERATURE DETECTION MILL COAL FEED IR BURNERS CLASSIFIER Figure 5 Ball Mills Suggestions for Enhanced Fire Detection on Double Ended Ball Mills The ball mill is a slow speed mill and has two primary areas where coal pockets can exist and

Coal Drying and Grinding Scribd. May 30, 2011 Instrumentation and Automation of the Coal Grinding Plant 8.. and filters, the temperature after a coal mill should be 15#176; 25#176;C higher than...

To summarize the coal mill controls, they may be divided basically into two major categories:. 1. To control the quality of coal being sent to the burners located on the furnace walls. The word quality here means the temperature and fineness of the PF. The set temperature values are dependent on the percentage of volatile matter that exists in the main fuel.

coal residue in 90 microns. From the above graph this very clear for coal type having 30% then recommended fine coal residue (+90 #181;) for kiln will be 15% and for use, it must be maximum 10%. And overall residue of 40% (kiln use) * 15% R90#181; + 60% (PC use) * 10% R90#181; = 12% R90#181; to be maintain while grinding in single mill.

#0183;#32;Coal mill hot air inlet temperatures should never be more than 600 #176; F and the outlet temperature should not exceed 200#176;F on Raymond coal mills. If the flow of raw coal to the coal mill is interrupted for any reason (for example: plugging, failure of the coal feeder, etc.), the outlet temperature of the coal mill can quickly climb to dangerous levels.

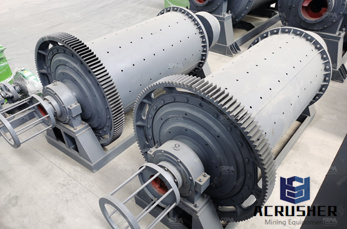

Coal ball mill is the equipment used for grinding and drying coal with different hardness. It is mainly composed of feeding device, principal axis, rotating part, transmission part, discharging part, highpressure starting device and lubrication system. It also widely used to bre

Coal Grinding Cement Plant Optimization

#0183;#32;At the same time mill outlet temp to maintain 20 0C above the dew point temp and for bituminous coal dew point temp is found to be 3335 0C. Secondly the speed of

balance equation of the coal significant heat contribution comes from the primary air flow, moisture of the incoming coal particles, coal flow into the mill and from grinding . The heat is used to evaporate the moisture and raise the temperature of the coal particles and the mill chassis to the outlet temperature

#0183;#32;Initially, this focused on grinding coal and the cement raw materials, with the adoption of vertical roller mills for cement product grinding with its finer grinding requirements coming more

Pulverized coal were sampled isokinetically from the PC pipes. The results indicate that there is a significant maldistribution of coal mass flow in the PC pipes. The particulate size was also coarse. As a result, the heat release from the combustion of coal occurred higher up in the boiler, leading to a flue gas exit temperature.

With adequate mill grinding capacity, a vertical mill equipped with a static classifier is capable of producing a coal fineness up to % or higher lt;50 mesh and 80% or higher lt;200 mesh, while one equipped with a dynamic classifier produces coal fineness levels of

Two major parameters which decide the mill capacity and performance are the hardness of coal and the total moisture level in coal. The mill outlet temperature of coalair mixture is maintained between 65 to 90 degree centigrade in the case of low and medium volatile coal. In the case of high volatile coal while the lower limit generally remains as 65 degree centigrade, the upper limit is

Coal grinding options in pyroprocessing Coal mill must operate at all times when burning coal. Direct Grinding/Firing System Grinding/Firing System Options Indirect Grinding: Fuel is pulverized and stored in a PulverizedMill exhaust gas temperature Recirculation of mill sweep air Self Inert System lt;10% during operation, not at start up. ~

Drying of moisture in coal is achieved normally by ducting part of the kiln exhaust gas through the mill with inlet temperatures of up to 300#176;C. Inert kiln exhaust gases with oxygen content of about 35% are most suitable for the intended purpose due to high risk of fire/explosion in fine coal.

#0183;#32;Initially, this focused on grinding coal and the cement raw materials, with the adoption of vertical roller mills for cement product grinding with its finer grinding requirements coming more

WhatsApp)

WhatsApp)