Conveyor Belt Replacement Procedure (Head

#0183;#32;Enjoy the videos and music you love, upload original content, and share it all with friends, family, and the world on YouTube.

WhatsApp)

WhatsApp)

#0183;#32;Enjoy the videos and music you love, upload original content, and share it all with friends, family, and the world on YouTube.

There are certain procedures and regulations that you must legally follow in order to meet the health and safety standards that have been set out. If you are using mobile cranes, construction equipment, mechanical plant and trucks from companies such as Babcock International, you need to comply with safety regulations to continue operating this machinery.

removal and replacement of belt, without unnecessary twisting or bending. Remove existing belt and track replacement belt onto rollers. Store removed belt appropriately. Ensure new belt is spliced according to procedures. 3. Commission conveyor belt. Inspect belt condition for imperfections or

Check our online catalogue to find the matching timing belt kit or timing belt kit with water pump for your application. What follows is a general stepbystep procedure for installing timing belts. Note that these are general guidelines. Carefully check the instructions of the vehicle manufacturer or our enginespecific instructions inside the

Replacement Reasoning The IBM seven step data mining procedure is recommended, using a closedloop feedback system to continuously improve the data mining. Data mining is considered to be an opportunity in manufacturing, but there are some drawbacks and

2. Do the positive isolation of all the electrical power sources of conveyor system. 3. Before changing/replacing of any component of the drive (coupling, gearbox or motor), do the positive isolation of potential energy source (takeup unit) of the belt by holding it with a pair of suitable chain blocks.

#0183;#32;Enjoy the videos and music you love, upload original content, and share it all with friends, family, and the world on YouTube.

Because coal mining operations use conveyor belts extensively to move materials, you must be able to count on your mining equipment to work efficiently without unscheduled downtime. Every time you have to stop production for unexpected problems like repairs or housekeeping, profitability drops.

Best Practice Conveyor Belt Systems Docstoc Documents . Jan 08, 2010 #183; #216; Operating procedures the South African conveyor and mining industry has focused heavily and passenger conveyors BS EN 1554:1999 Conveyor belts #187;More detailed

Mining Conveyor Belt Replacement or Repair in Ireland Ireland is the largest producer of zinc concentrate in the EU, our mines depend on the quality of their equipment and machinery. Mining conveyor belting is a big part of everything they do and when it malfunctions, breaks or gets damaged... time is a key factor for repairing or replacing their conveyor belting and getting them back on track.

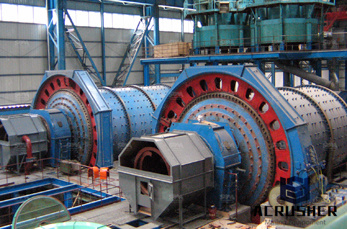

Mining Conveyor Belts. We can repair or replace conveyor belts on your conveyor belting machine and bulk mining machines. All types of Mining replacement belts for: belt conveyors for bulk mining, belt conveyors for mechanical mining and crushing line belt conveyor. Call 087 354 8653 to replace your Mining conveyor belt Today

d) Reinstalling the belt. e) Using an approved VW M8 flanged nut, of which the flange is a 17 mm. (It is not recommended to use a standard M8 Nut and a flat washer.) Belt and Tensioner Removal: Once the procedure for setting the TDC is completed according to VWs guidelines: 3. Slacken tensioner nut. 4.

Improving Belt Conveyor Safety With Better Procedures and Training708 . Belt Tracking Procedures. The Double Benefit of Conveyor Training In fact, training in conveyor operations provides the best of both worlds. It presents an opportunity to provide training on worker safety that will in fact improve an operations operating efficiency.

Thumbs up for belt replacement September 14, 2007 News s11_admin DAMPIER costal operations 6 km long C208 belt, was replaced recently following three months of work.

To avoid damaging belt edges you should use a spreader bar. The best practice for running out the belt is to use a braked stand. Small roll can be pulled from a freewheeling stand, however care should be taken to avoid the belt from running away. If the belt is to be dragged along the ground, then care should be taken to ensure that no objects are

conveyor belt replacement procedure. All conveyor belt replacement procedure wholesalers amp; conveyor belt replacement procedure manufacturers come from members. We doesn''t provide conveyor belt replacement procedure products or service, please contact them directly and verify their companies info carefully.

Mining Conveyor Belt Replacement or Repair in Ireland Ireland is the largest producer of zinc concentrate in the EU, our mines depend on the quality of their equipment and machinery. Mining conveyor belting is a big part of everything they do and when it malfunctions, breaks or gets damaged... time is a key factor for repairing or replacing their conveyor belting and getting them back on track.

WhatsApp)

WhatsApp)