Ball Mill Critical Speed amp; Working Principle YouTube

Jun 19, 2015#0183;#32;https:// Learn about Ball Mill Critical Speed and its effect on inner charge movements. The effect of Ball Mill RPM s...

WhatsApp)

WhatsApp)

Jun 19, 2015#0183;#32;https:// Learn about Ball Mill Critical Speed and its effect on inner charge movements. The effect of Ball Mill RPM s...

The critical speed of ball mill is given by, where R = radius of ball mill r = radius of ball. For R = 1000 mm and r = 50 mm, n c = rpm. But the mill is operated at a speed of 15 rpm.

The interaction critical speed (nc) of this mill is around 77 rpm and the recommended operating speed is 70%... Read more The Influence of Ball Mill Critical Speed on Production Efficiency

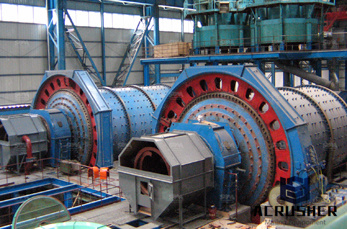

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about its axis. T

Jun 20, 2015#0183;#32;https:// Learn about Ball Mill Critical Speed and its effect on inner charge movements. The effect of Ball Mill RPM s...

Effect of Mill Speed on the Energy Input In this experiment the overall motion of the assembly of 62 balls of two different sizes was studied. The mill was rotated at 50, 62, 75 and 90% of the critical speed. Six lifter bars of rectangular crosssection were used at equal spacing. The overall motion of the balls at the end of five revolutions is shown in Figure 4. As can be seen from the

Critical Speed of Ball Mill Source: clirik By Administrator Posted: Critical Speed of Ball Mill For a ball mill, it does not have a constant critical speed, because of the centrifugalization of the steel balls is different according to different resistance and friction between ball loads But the ball speed of centrifugalization is constant

critical speed for a ball mill . Second Hand Concrete Batching Plants For Sale In Malaysia. Market of Second Hand Concrete Batching Plants For Sale In MalaysiaDevelopment of Second Hand Concrete Batching Plants are to largescale, automated, intelligen. Raw Complex Gold Ore Processing Machine.

The ideal mill speed is usually somewhere between 55% to 75% of critical speed. Critical Mill Speed. Critical Speed (left) is the speed at which the outer layer of media centrifuges against the wall. Second Critical Speed (middle) is the speed at which the second layer of media centrifuges inside the first layer.

derivation of critical speed of ball mill. The critical speed of the mill, amp;c, is defined as the speed at which a single ball will just remain against the wall for a. LG A mill power equation for SAG mills. Request Quotation. balls, time of grinding, particle density and speed of the ball mill (rpm) have been considered Read more

A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shells inside surface and no balls will fall from its position onto the shell. The imagery below helps explain what goes on inside a mill as speed varies. Use our online formula The mill speed is typically defined as the percent of the Theoretical

The point where the mill becomes a centrifuge is called the quot;Critical Speedquot;, and ball mills usually operate at 65% to 75% of the critical speed. Ball Mills are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns.

Formula For Critical Velocity Of Ball Mill Pdf . The quot;Critical Speedquot; for a grinding mill is defined as the formula to calculate critical speed in ball mill . Get Price And Support Online; Ball Mills Mine This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

derivation of critical speed of ball mill. The critical speed of the mill, amp;c, is defined as the speed at which a single ball will just remain against the wall for a. LG A mill power equation for SAG mills. Request Quotation. balls, time of grinding, particle density and speed of

The critical speed of ball mill is given by, where R = radius of ball mill; r = radius of ball. For R = 1000 mm and r = 50 mm, n c = rpm. But the mill is operated at a speed of 15 rpm. Therefore, the mill is operated at 100 x 15/ = % of critical speed. get price.

A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell''s... Get Price. Pyrotechnics Ball Mill Theory. BALL MILL THEORY AND PRACTICE. Speed formula for fastest milling ... the critical speed of the jar, and is calculable for a specific jar

The critical speed of ball mill is given by, where R = radius of ball mill; r = radius of ball. For R = 1000 mm and r = 50 mm, n c = rpm. But the mill is operated at a speed of 15 rpm. Therefore, the mill is operated at 100 x 15/ = % of critical speed.

critical speed of ball mill from wiki Bart Swennenhuis Ball Mill Progressive Industries, Inc ball mill critical speed,APT Ball Mills have been successfully run at speeds between 60 and 90 percent of critical speed However, most APT Ball Mills operate at speeds between 65 and 75 percent of critical speed The larger the diameter, the slower the rotation,.formula for critical speed of ball mill.

Mill Critical Speed Determination. The quot;Critical Speedquot; for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces at the mill shell''s inside surface. This is the rotational speed where balls will not fall away from the mill''s shell. Result #1: This mill would need to spin at RPM to be at critical speed.

The point where the mill becomes a centrifuge is called the quot;Critical Speedquot;, and ball mills usually operate at 65% to 75% of the critical speed. Ball Mills are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns.

.:. Mill Critical Speed Determination

WhatsApp)

WhatsApp)