Ball Mill Trunnion Bearing Installation Lafarge Ndola

24/12/2019#0183;#32;Installation of a ball mill. particular emphasis of video is how to install the trunnion bearings, scraping, etc. ideal for total beginners. doesnt go into m...

WhatsApp)

WhatsApp)

24/12/2019#0183;#32;Installation of a ball mill. particular emphasis of video is how to install the trunnion bearings, scraping, etc. ideal for total beginners. doesnt go into m...

The Main Bearing Installation Of Ball Mill ATS Mining Bearing Installation Ball Mill Mine Equipments. To ensure the normal work of guan jian of ball mill zk mining installation of ball mill the first step should be to install the main bearing in order to prevent exacerbation

Because of the arduous nature of the ball mill application and the time it takes to manufacture these colossal bearings, OKeefe says having a reliable supplier is essential.

(2)The installation of the ball mill main bearing The process of installation should make sure the normal rotation of the journal and the bearing, and good connection with each other. The two hollow shafts should have the same axial gradient, and there should be between the center shaft and bearing.

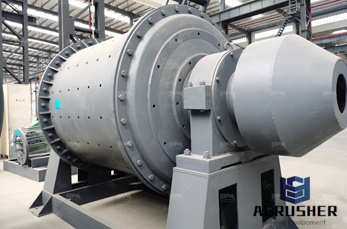

A ball mill can be installed on top of the concrete base when its compressive strength is up to more than 75%. Before installation, check the quality of the basis to ensure that concrete is not affected by the strength of the defect, the number and position of the reserved hole meets the requirements, and the reserved holes have no water, without oil stain.

11/05/2020#0183;#32;From a bearing point of view, there are two bearings at the end of the shaft on the pinion and there are two bearings on either end of the ball mill. And obviously, the ball mill bearings are

Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available. As such you will find it is designed and constructed according to heavy duty specifications. It is designed along sound engineering principles

Internal Clearance. In the manufacture of ball bearings, standard practice indicates assembling the rings and balls with a specified internal clearance. This characteristic proves necessary to provide preengineered clearance to compensate for the tight fit effects of press fitting the bearing rings on shafts or housings at installation. Internal clearances compensate for thermal expansion of bearings, shafts and

After the installation of the ball mill is completed, start to run with load, add 70% of the specified load into the grinding material, and continue to run for more than 10 hours. During this process, the liner bolt joint should be fastened and check the bolt connection frequently to prevent the loosen.

Jul 28, 2020#183; Ball mill installation is a must step before it is put into production, which will affect the subsequent use of the ball mill, and even affect the production volume, crushing rate, service life, etc., so the importance of ball mill installation is selfevident.. In addition, the choice of grinding medium is

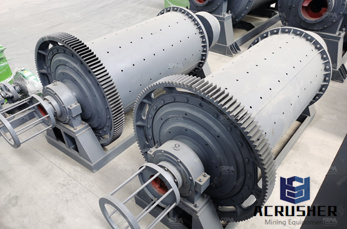

28/07/2020#0183;#32;Steps to install the ball mill 1. The installation of the chassisThere are four chassis should be installed: the front tile base, the rear tile base,... 2. The installation of the main bearingThe distance between the centerlines of the chassis of the two bearings shall be... 3. The installation of

Ball mill grinder installation accomplishment according to the paper, to ensure all the components are at the right position. The complete installation process should be recorded and acceptance passed. Equipment base concrete strength and secondary grouting concrete strength are up to the strength level of design requirement. The PLC controlling system, thermometer, and pressure gauge of ball mill

Metallurgical ContentBall Mill TRUNNION BEARINGSTrunnion BRONZE BUSHINGSTRUNNION BASE AND CAPBall Mill LUBRICANT JACKSBall Mill PINION SHAFT BEARINGS The first part of the mill that we will look at is the TRUNNION BEARING. This is a HYDROSTATIC BEARING which is a slow moving bearing that carries a heavy load. Usually it is constructed from Babbitts metal. If you happen to

Trunnion Bearing Assembly Ball Mill amp; Rod Mill

WhatsApp)

WhatsApp)