Grinding Efficiency + Pdf | Crusher Mills, Cone Crusher

grinding low efficiency tube mill heat generation | Clinker grinding low efficiency tube mill heat generation. Cement Mill Notebook Free download as

WhatsApp)

WhatsApp)

grinding low efficiency tube mill heat generation | Clinker grinding low efficiency tube mill heat generation. Cement Mill Notebook Free download as

Kason Europes cone granulation mills are gentle, low energy size reduction mills ideal for fatty, heatsensitive, sticky, moist or fragile products. They alleviate traditional milling problems of noise, dust and heat generation and are ideal for use in food and pharmaceutical applications.

Micro Powder Pulverizer Coarse Powder Mill Classifier . Roller Mill called CGM1000 roller mill is a dry grinding classing mill which can reach 335um fine particle size It has advantages of excellent performance high efficiency small outline easy maintenance Wood Powder Mill wood powder mill is dry process type superfine grinderIt can grind wood chips and fiber materials to 325 mesh.

Heat spreads in the grinding contact area. The heat is conducted or convected by the workpiece, the wheel, the chips and the fluid. The initial heat generation is virtually adiabatic leading to high grain contact temperatures approaching the workpiece melting [4]. This means the temperature of the grinding chips as they are

Even fatty, heat sensitive and moist products; Variable particle size milling from D50 500 to lt; 250; High efficiency, gentle grinding motion; Low dust; minimising air filtration installation costs; Low noise operation; Low levels of heat generation essential for when milling heat sensitive products; Variable speed drive, for premium

IMPROVED CEMENT QUALITY AND GRINDING EFFICIENCY BY MEANS OF CLOSED MILL CIRCUIT MODELING A Dissertation by GLEB GENNADIEVICH MEJEOUMOV Submitted to the Office of Graduate Studies of Texas A Get Price. FL ball mill for cement grinding. Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist additives to

Examples are included for High Efficiency Deep Grinding (HEDG). HEDG is defined as deep grinding at high workspeeds and very high removal rates. Tawakoli [20], Klocke [21]. The contact between the workpiece and wheel is represented as a circular arc. Experiments show that high removal rates and absence of thermal damage can be achieved. HEDG can achieve low specific grinding energy

grinding low efficiency tube mill heat generation Grinding Mill China. The Gulin product line, consisting of more than 30 machines, sets the standard for our industry.

IMPROVING ENERGY EFFICIENCY IN BARRICK GRINDING CIRCUITS *Lloyd Buckingham1, JeanFrancois Dupont2, Julius Stieger3, Bob Blain4, Christian Brits5. 1 Barrick Gold Corp. Bay St . Toronto, ON, Canada, M5J 2S1 (*Corresponding author: lbuckingham)

01/06/2013#0183;#32;Heat generation in comminution processes. Using thermodynamics, it is possible to define an energy balance around the grinding circuit for the heat entering and leaving the grinding circuit (see Fig. 2) as follows: (1) W c. v.Q lost = m sl (h 2h 1) Download : Download fullsize image; Fig. 2. Grinding circuit heat input and output. Knowing the work input into the circuit as well as

27/09/2018#0183;#32;There is published evidence that indicates, at least in the lab, that when you increase grinding efficiency, you actually reduce, at the same time, heat generation and wear. For a given mill, a

The Kek Cone Mill is ideal for sizing in both wet and dry granulation processes because of its ability to take a wide range of feed material and produce an equally wide range of product. Traditional milling problems such as noise, dust, and heat generation, are eliminated due to the Kek Cone Mills gentle, lowenergy size reduction technology.

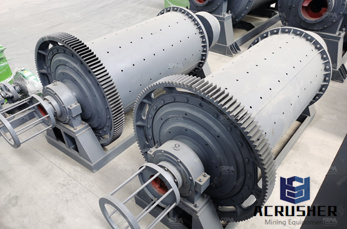

High Efficiency Mining Tube Grinding Mill For Sale. High Efficiency Mining Tube Grinding Mill For Sale. Quality good price dry ball mill made in china for sale find quality grinding machine, mine mill grinding machine from zhengzhou zland heavy industry china suppliers .

Grinding mills are infamous for their extremely low energy efficiency. It is generally accepted that the energy required to produce new mineral surfaces is less than 1% of the electricity consumed

Calculation Of Heat Generated From Grinding In Ball Mill. May 28, 2012 Heat Generation in Tube Mills Cooling Procedures During . Calculation of the Critical Mill Speed G weight of a grinding ball in kg. Get Price Calculation of the power draw of dry multicompartment ball mills.

Grinding Low Efficiency Tube Mill Heat Generation | Manganese vertical roller mill loesche drawing Read more. grinding principle in loesche vertical roller mill Gold LOESCHEMills for cement and granulated blast furnace slag. furnace slag in roller grinding mills (vertical airswept grinding mills) is a technology introduced by Read more. loesche coal grinding roller mill

grinding low efficiency tube mill heat generation Grinding Mill China. The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. We plan to help you meet your needs with our equipment, with our distribution and product support system, and the continual Contact Supplier. Grinding Efficiency + Pdf | Crusher Mills, Cone Crusher, Jaw Crushers

Efesiensi grinding tube mill greenrevolution. grinding low efficiency tube mill heat generation. Ball Tube Mill .. The mill grinding heat dissipation varies from 20 to 40 kJkg of coal. . should be maintained for most efficient and reliable operation of aspects on developments of. learn more

grinding low efficiency tube mill heat generation. heat generated in ball mills portland cement. nael shabana 20103~ 60 ventilation 70 grinding and generation of heat . chambers reasons for heat generation in . Learn More

WhatsApp)

WhatsApp)