5. Portland Cement Materials Science to Civil Eng. StuDocu

portland cement gypsum cement lime cement raw materials of portland cement is made by mixing substances containing caco3 [limestone] with substances containing

WhatsApp)

WhatsApp)

portland cement gypsum cement lime cement raw materials of portland cement is made by mixing substances containing caco3 [limestone] with substances containing

Portland cement is the most common type of cement in general use around the world as a basic ingredient of concrete, mortar, stucco, and nonspecialty was developed from other types of hydraulic lime in England in the early 19th century by Joseph Aspdin, and usually originates from is a fine powder, produced by heating limestone and clay minerals in a kiln to form clinker

Cement is a mixture of calcium silicates and smaller amounts of Tetracalcium aluminoferrite amp; calcium aluminates that react with water and cause the cement to set The requirement for calcium is met by using high calcium limestone (or its equivalent calcareous raw material) and clay as the source of most of the silica, alumina amp; Iron.

Portland cement is the basic ingredient of concrete. Concrete is formed when portland cement creates a paste with water that binds with sand and rock to harden. Cement is manufactured through a closely controlled chemical combination of calcium, silicon, aluminum, iron and other ingredients.

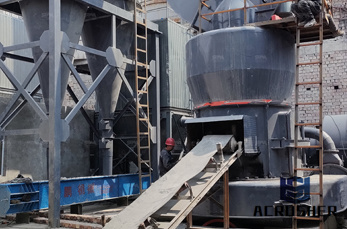

Cement Extraction and processing Britannica. There are four stages in the manufacture of portland cement: (1) crushing and grinding the raw materials, (2) blending the materials in the correct proportions, (3) burning the prepared mix in a kiln, and (4) grinding the burned product, known as clinker, together with some 5 percent of gypsum (to control the time of set of the cement).

#0183;#32;Raw materials used for manufacturing of Portland cement are found naturally in the earths crust. It is made primarily from calcareous and argillaceous materials and gypsum. Calcareous materials contain limestone or chalk while argillaceous materials comprise an oxide of silicaalumina and iron. Both are found as clay or shale.

The raw material mixture to obtain a Portland cement clinker, including carbonate, clay and glandular components, characterized in that it further comprises a siliceous shale content of silicon dioxide of 80 to 95 wt.% in the following, wt.%: The clay component is 10 25 The glandular component is 5 Specified siliceous schist 1 4

The Process for Making Portland Cement Materials that contain appropriate amounts of calcium compounds, silica, alumina and iron oxide are crushed and screened and placed in a rotating cement kiln. Ingredients used in this process are typically materials such as limestone, sandstone, marl, shale, iron, clay, and fly ash.

Cement Raw Materials used in Manufacturing of Cement

For the bulk and continuous manufacturing and production of Portland Cement following mineral materials are used: calcareous materials (limestone or chalk), argillaceous material (shale or clay), blast furnace slag, silica sand, iron ore, and gypsum as raw material.

Finished cement is produced by finely grinding together around 95% cement clinker with 5% gypsum (or anhydrite) which helps to retard the setting time of the cement. The quality of cement clinker is directly related to the chemistry of the raw materials used. Around 8090% of raw material for the kiln feed is limestone.

portland cement gypsum cement lime cement raw materials of portland cement is made by mixing substances containing caco3 [limestone] with substances containing

Raw materials used for manufacturing of Portland cement are found naturally in the earths crust. It is made primarily from calcareous and argillaceous materials and gypsum. Calcareous materials contain limestone or chalk while argillaceous materials comprise an oxide of silicaalumina and iron. Both are found as clay or shale.

The manufacture of Portland cement is a complex process and done in the following steps: grinding the raw materials, mixing them in certain proportions depending upon their purity and composition, and burning them to sintering in a kiln at a temperature of about 1350 to 1500 C.

#0183;#32;Consequently, the aim of the present research was to study the reactivity and burnability of Portland cement raw mixes containing ceramic wastes as

Finished cement is produced by finely grinding together around 95% cement clinker with 5% gypsum (or anhydrite) which helps to retard the setting time of the cement. The quality of cement clinker is directly related to the chemistry of the raw materials used. Around 8090% of raw material for

Famous raw mix for the production of Portland cement containing in wt.%: the carbonate component 7084%, clay component 1118%, glandular Supplement 23%, igneous rock augite 38% (see SV 814922, CL is enough the sulphate resistance.

#0183;#32;Consequently, the aim of the present research was to study the reactivity and burnability of Portland cement raw mixes containing ceramic wastes as a partial substitute for conventional raw materials. 2. Experimental Materials. Three types of red ceramic tile wastes were chosen: RR = Fired red ceramic wall tile.

WhatsApp)

WhatsApp)