Can we make concrete using quarry dust as a replacement

Yes As quarry dust(also called as crushed sand) is a byproduct obtained after crushing of stones(rocks) to make aggregates. * Results have shown that the concrete

WhatsApp)

WhatsApp)

Yes As quarry dust(also called as crushed sand) is a byproduct obtained after crushing of stones(rocks) to make aggregates. * Results have shown that the concrete

Experimental study on sand replacement with bagasse ash crusher dust blended in the concrete as sand replacement in pavement construction literature survey in line with this project shows a high potential for partial replacement of sand in concrete with bagasse ash and crusher stone dust which give the better results when these two materials are mixed up in the partial replacement of sand

investigate the influence replacement of natural sand by stone dust (5%, 10%, 15%, 20%, 25% and 30%) in workability, air content, compressive strength, impact strength, permeability and retraction of concrete samples. It was found that the 10% of replacement increased the compressive strength of concrete; however, 5% of stone dust was

2. LITERATURE REVIEW A work done by Sunilaa [1] was focused on replacement of river sand using manufactured sand and quarry dust in cement concrete. The materials used to prepare concrete was Ordinary Portland Cement (OPC 43 Grade), river sand,

replacement of sand at an interval of 10%. Again above tests are carried out with 20% replacement of cement by glass powder. It is observed that the glass powder improve the strength and stone dust can be used as sand. This is great saving in costly material. Keywords Stone Dust

Dec 01, 2017#0183;#32;Three replacement levels of 0%, 25% and quarry dust were used in the concrete mixes. The 25% is the optimum replacement percentage achieved by carrying out strength studies for 0%, 25%, 50%, 75% and sand replacement levels. The respective 28day strengths were,,, and N/mm 2 [18].

LITERATURE REVIEW Djwantoro Hardjito, et al (1992) portrayed the impacts of a few factors on the properties of fly fiery remains based Geo Polymer concrete, particularly the compressive quality. The test Studies on Geo Polymer Concrete with Partial Replacement of Sand by Quarry Stone Dust (Qsd)

The compressive strength of 05% stone dust and ceramic waste sample is in close proximity of the referral concrete. Thus, it can be concluded that stone dust up to 05% with 05% ceramic waste aggregate is satisfactory for use. Results show that with partial replacement of stone dust with 05% and 05% Ceramic waste coarse

In order to study the strength behaviour and fire resistance of the concrete made with full replacement of sand with Quarry stone dust the tests are conducted. Results so obtained for the tests conducted on cubes and prisms for M25 and M40 grades of concrete with various dosages of super plasticiser at 7days and 28 days were tabulated.

Results shows natural sand can be effectively replace with stone dust and maximum strength attains at 60 percent replacement of natural sand with stone dust based on compressive strength. View

of concrete when sand was partially replaced by stone dust up to 40 percent. Tripathy and Barai (2006) investigated the compressive strength of mortar made with crusher stone dust (CSD) under normal, hot water curing and autoclaving curing. They concluded that up to

Stone dust passing by No. 200 sieve, is used as cement replacing material and retained by No. 100 sieve is used for sand replacement. Sand was replaced by stone dust of 15%, 20%, 25%, 30%, 35%, 40...

stone dust decreases workability of concrete due to the larger portions of fine particles. At 75% of sand replacement, the percentage of increase in compressive and tensile strength were 40 and 28 compared with references mix respectively. 5. Chaturanga Lakshmi Kapugamage (2008) have reported about the use of fly ash and quarry

Partial replacement of fine aggregates literature review for sand stone with artificial fine aggregate in. Live Chat; Study on compressive strength of quarry dust as fine aggregate suitability of quarry dust as a sand replacement

concrete with stone dust as fine aggregate, draws the following conclusionsThe concrete cubes with crusher dust developed about 17% higher strength in compression, 7% more split tensile strength and 20% more flexural strength (Modulus of Rupture) than the Concrete cubes/beams with river sand

Jan 01, 2018#0183;#32;The deficit of natural sand arise the need of alternative materials for replacement of natural sand. This experimental study explores in detail the crushed stone dust which is locally available industrial solid waste material in India as alternative material to natural sand that is being conventionally used as fine aggregate in cement concrete.

Stone Dust and Stone Screenings in NJ amp; NY | Atak Trucking. Stone Dust Delivery NJ and NY Stone dust, also referred to as stone screenings or #10 stone, is available for delivery at wholesale pricing from ATAK Trucking If you are interested in stone dust bulk delivery in NJ and Staten Island, we offer the stone dust you need at competitive wholesale pric As a leading supplier of stone dust and

Aug 30, 2019#0183;#32;It is also reported that 40% replacement of stone dust with sand improves the mechanical properties of concrete . The more the stone dust, the worse the mechanical properties [11] . In a study that used quarry dust and 10mm washed aggregate as a fine aggregate, it was observed that standards were fully met even at full replacement and that the amount of water absorbed increased [12] .

Would you like to get the full Thesis from Shodh ganga along with citation details?

This experimental study presents the variation in the strength of concrete when replacing sand by quarry dust from 0% to in steps of 10%. M20 and M25 grades of concrete were taken for study keeping a constant slump of 60mm. The compressive strength of concrete cubes at the age of 7 and 28 days were obtained at room temperature. Also the temperature effect on concrete cubes at 100 o C on

literature review on stone quarry home built jaw crusher Stone crushing machine pdf literature review on installation of a jaw crusher we provide customers with a variety of good quality construction and mining crushing equipment, and optimize the combination of various types

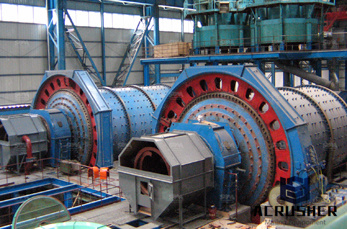

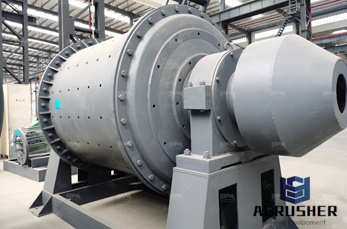

Stone dust is what you get in the process of crusher run where stones are run through a crusher machine. This byproduct itself can be of great use to create the bedding layer of paver projects. You can think of stone dust as a rougher variation of sand. It is also known as rock dust, quarry dust

WhatsApp)

WhatsApp)