Mining Processing Of Slate

Slate | Minerals Education Coalition

WhatsApp)

WhatsApp)

Slate | Minerals Education Coalition

Immigration into the Slate Valley. Then in the 1850s demand for roofing material emerged. Slate roofs could last 100 to 150 years, if properly maintained. Processing of slate for roofing required special skills which existed in abundance in Wales. The Welsh had been mining and processing slate since 1399. Skilled Welsh workers immigrated to the Slate Valley in droves.

Characterization of slate processing fines according to . Slate processing fines (SPF) are mineral wastes produced during the preparation of roofing slate Slate is extracted in opencast quarries that often result in disturbed sites and wastes that are thrown into dumps which are inhospitable to vegetation due to their poor water holding capacity and limited capability to supply nutrients

A coal breaker is a coal processing plant which breaks coal into various useful sizes. Coal breakers also remove impurities from the coal (typically slate) and deposit them into a culm coal breaker is a forerunner of the modern coal preparation plant.. Coal tipples typically were used at bituminous coal mines, where removing impurities was important but sorting by size was only a

mining processing of slate in iran. Mining in Iran Mining in Iran is underdeveloped yet the country is one of the most important mineral producers in the world ranked among 15 major mineralrich countries holding some 68 types of minerals 37 billion tonnes of proven reserves and more than 57 billion tonnes of potential reserves worth 770 billion in 2014

slate mining process Crushing and Screening Plant. About process of mining slaterelated informationsujatha slate pencil jeevan news youtube 27 apr 2012 slate pencil production technology kettathum kandathum 9 Slate Mining Process The mine is still working and you can see the whole slate mining process including slate sawing and splitting and even buy the finished product as a souvenir

Slate can be quarried in a slate quarry or tunneled in a slate mine. The slate industry revolves around extraction and processing of slate for most of its uses such as roofing or flooring. Slate mines are abundant in several cities in the world, including Wales in the United Kingdom, which is considered a major industry in the region.

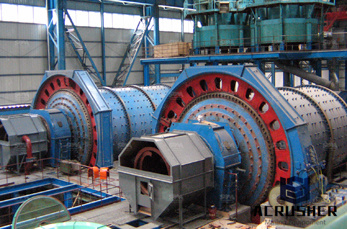

From the following introduction, you will learn the whole slate mining process. Vibrating feeder feeds and screens the bulk slate evenly, the soil and impurities of which are removed, too. Then the slate is conveyed into jaw crusher for the primary crushing. The maximum feed size of jaw crusher is between mm.

The slate industry is the industry related to the extraction and processing of slate. Slate is either quarried from a slate quarry or reached by tunneling in a slate mine. Common uses for slate include as a roofing material, a flooring material, gravestones and memorial tablets, and for electrical insulation.

mining processing of slate. mining processing of slate . Mining: Mining, process of extracting useful minerals from the surface of the Earth, including the seas. A mineral, with a few exceptions, is an inorganic substance occurring in nature that has a definite chemical composition and distinctive physical properties or molecular structure.

Slate industry Wikipedia. The slate industry is the industry related to the extraction and processing of is either quarried from a slate quarry or reached by tunneling in a slate mine mon uses for slate include as a roofing material, a flooring material, gravestones and memorial tablets, and for electrical insulation.

Slate Mining Process Crushing And Screening Plant. About process of mining slaterelated informationsujatha slate pencil jeevan news youtube 27 apr 2012 slate pencil production technology kettathum kandathum 9 slate mining process the mine is still working and you can see the whole slate mining process including slate sawing and splitting and even buy the finished product as a souvenir

Mining Process. The conversion of natural stone (marble, granite, slate, etc.) from the quarried mineral to the decorative home accent is a timely process. Blocks are cut from the natural quarries and transported to factories for cuts into slabs and tiles. Midwest Tile, Marble amp; Granite Incs product lines originate from quarries in countries such as:

Quarry, place where dimension stone or aggregate (sand, gravel, crushed rock) is mined. The products of dimension stone quarries are prismatic blocks of rock such as marble, granite, limestone, sandstone, and slate. After cutting and polishing, these materials are used in the primary construction

No mining or bluestone exploration activities will be allowed after the expiration date of the bluestone exploration authorization, unless a mining permit has been issued. SmallScale Bluestone Mines. Since March 3, 1999, a smallscale bluestone mining application has been available to operators of

The process is relatively simple: locate or create breaks in the stone, remove the stone using heavy machinery, secure the stone on a vehicle for transport, and move the material to storage and processing. Uses. Slates foliation allows it to be broken into sheets of any desired thickness.

slate mining process Crushing and Screening Plant. Work Flow of Slate Mining Process: Vibrating feeder feeds and screens the bulk slate evenly, the soil and impurities of which are removed, too. Then the slate is conveyed into jaw crusher for the primary crushing. The maximum feed size of jaw crusher is between mm.

In the coal mining industry of the Appalachian Basin, the word quot;slatequot; is still used by many miners in reference to the shale that forms the roof and floor of a mine, and for fragments of shale that are separated from the coal in preparation plants. Experienced miners train newer miners, and archaic language is passed along.

WhatsApp)

WhatsApp)