Calculating Ball Mill Throughput

Calculate and Select Ball Mill Ball Size for Optimum Grinding Aug 2, 2013 ball charge volume and mill throughput, if the mill power draw is calculated Read more throughput calculation plate mill

WhatsApp)

WhatsApp)

Calculate and Select Ball Mill Ball Size for Optimum Grinding Aug 2, 2013 ball charge volume and mill throughput, if the mill power draw is calculated Read more throughput calculation plate mill

Quite often, there is a need for a quick and correct calculation of a grinding ball surface area and volume. Necessity of such calculations may arise when choosing a container for reloading grinding media into a ball mill;when selecting the optimum characteristics of grinding ballsto suit specific grinding

Mill Speed is commonly given either as the number (AO of revolutions per minute, or as is frequently treated as equal to (bulk volume of grinding media) = (mill volume). Vibratory ball mills agitate a charge by means of oscillating springs.

Media and Product Ball Mill Loading Guide (Percentages are based on total volume of cylinder) NOTE: With media load at 50%, voids are created equal to 20% of cylinder volume. These voids are filled when product is loaded into the mill. Mills can be loaded by volume

Dec 12, 2016#0183;#32;Ball Mill Power Calculation Example A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of

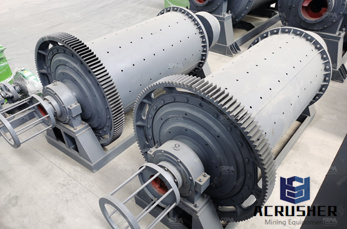

May 22, 2019#0183;#32;The ball mill consists of a metal cylinder and a ball. The working principle is that when the cylinder is rotated, the grinding body (ball) and the object to be polished (material) installed in the cylinder are rotated by the cylinder under the action of friction and centrifugal force.

The number of lifters generally can be determined by the ruleofthumb: Number of Lifters = 3nD for double wave liners. = for single wave liners where D is the mill diameter (m). Double wave liners are more suitable for ball sizes less than 60 mm. Otherwise, single wave is preferred.

Oct 19, 2017#0183;#32;Lets sum up. The grinding balls diameter determined by the Bond formula has a recommendatory character and serves as a starting point for calculating the necessary proportion grinding media feeding a new mill. More precisely adjust the ball load in the mill

R the radius of the ball. The volume of a grinding ball is determined by the formula: V=4/3**R 3, where: V the volume of the ball. PI constant, a mathematical constant that is equal to the ratio of the circles circumference to its diameter. is a commonly used value for PI; R the radius of the ball.

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum chunk size, product size as P80 and maximum and finally the type of circuit open/closed

The load estimation method has you physically measure distances in the mill. Follow the charts below and pull them into this calculator. If you can clearly see inside the mill, use the liner method.

The geometry of a mill with conical ends is shown in Figure The total volume inside the mill is given by Vm 4 D2 mL 1 2(Lc L) L 1 (Dt/Dm) 3 1 Dt/Dm () The density of the charge must account for all of the material in the mill including the media which may be steel balls in a ball mill

Ball Mill Capacity Calculation Jaw Crusher Technology . Ball mill capacity calculation jaw crusher technology bond ball mill index jktecha bond ball mill index test (bbmwi) is a standard test for determining the ball mill work index of a crushing and grinding calculations part i and iibritishget price.

A) Total Apparent Volumetric Charge Filling including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls expressed as a percentage of the net internal mill volume (inside liners). B) Overflow Discharge Mills operating at low ball fillings slurry may accumulate on top of the ball charge; causing, the Total Charge Filling Level to

Sep 29, 2020#0183;#32;An industrial ball mill operating in closedcircuit with hydrocyclones was studied by five sampling surveys. The aim of the present study was to optimise operating parameters ( charge volume

The sizing of ball mills and ball milling circuits from laboratory grinding tests is largely a question of applying empirical equations or factors based on accumulated experience. Different manufacturers use different methods, and it is difficult to check the validity of the sizing estimates when estimates from different sources are widely divergent. It is especially difficult to teach mill

Calculate Ball Mill Loading passeport emploi be. Calculate ball mill loading ball mill capacity formula volume loading formula in ball mill house volume loading formula in ball mill housean m diameter sag mill with lid grinding a copper ore and predicted maximum capacity and minimum kwhton at about ball load at is the volume fraction of solid in the slurry the calculation of the effective

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize just in case. Well, this safety factor can cost you much in recovery and/or mill liner wear and

We can calculate the steel charge volume of a ball or rod mill and express it as the % of the volume within the liners that is filled with grinding media. While the mill is stopped, the charge volume can be gotten by measuring the diameter inside the liners and the distance from the top of the charge to the top of the mill. The % loading or change volume can then be read off the graph below or

WhatsApp)

WhatsApp)