World iron ore reserves by country 2018 | Statista

How much iron ore is left in the world? This statistic shows the world iron ore reserves as of 2018, by major countries. The reserves of crude iron ore in the United States were estimated to be

WhatsApp)

WhatsApp)

How much iron ore is left in the world? This statistic shows the world iron ore reserves as of 2018, by major countries. The reserves of crude iron ore in the United States were estimated to be

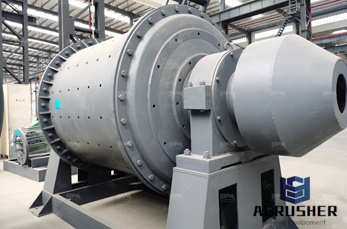

Iron Ore Efficiently remove silica and alumina contamination to increase efficiencies in steel production Our iron ore processing plants are proven to successfully deal with silica and alumina contamination in the iron ore resulting in an increase in the Fe value of the iron ore thereby increasing the water washing plant in iron ore.

#0183;#32;To use the ore washing plant, there are several requirements that it needs. Here are the following things that you need before you start: Constant supply of energy with no EUP greater than 32 EU. Steady stream of water via pumps or water brought in through containers. Your crushed ores. And, patience. It takes time to purify those ores!

Process For The Treatment Of Wash Water From The Gas. 199376The invention relates to a process for the treatment of wash water from the gas washing system of an iron ore reduction plant the wash water being brought into direct contact with dustladen gas in a gas washer is removed from the latter and after solids separation is again supplied in cooled form to the gas washer.

Article Washing iron ore reserves to ensure maximum efficiencies in steel production. There are numerous reasons why it is beneficial to introduce washing of raw iron ore reserves to increase efficiencies in steel production and maximise revenues fro...

Iron ores are rocks and minerals from which metallic iron can be economically extracted. The ores are usually rich in iron oxides and vary in color from dark grey, bright yellow, or deep purple to rusty red. The iron is usually found in the form of magnetite (Fe 3 O 4, % Fe), hematite (Fe 2 O 3, % Fe), goethite (FeO(OH), % Fe), limonite (FeO(OH)#183;n(H 2 O), 55% Fe) or siderite (FeCO

Spirals require addition of water at various points down the spiral to assist washing of the iron ore, transporting away the light gangue from the dense ore. The amount of wash water and its distribution down the spiral trough can be adjusted to meet the operating requirements.

#0183;#32;Ironore sintering gas cleaning residue is . Available online at The 7 th International Conference on Waste Management and Technology Waterwashing of ironore sintering gas cleaning residue for So optimizing water washing condition is focused on to minimize the transfer amount of these heavy

These processes result in a wide range of water use from 124 to 11,300 gallons of water per ton of iron ore concentrate. Water use in con#173; centration plants is related to the physical state of the ore.

#0183;#32;Iron ore is a mineral block found underground. It is smelted into iron ingots, which are used to make tools and armor. 1 Obtaining Breaking Natural generation 2 Usage Smelting ingredient Note Blocks 3 Sounds 4 Data values ID 5 Video 6 History 7 Issues 8 Trivia 9 Gallery Iron ore must be mined with a stone pickaxe or higher, or else it drops nothing. Unlike most ores, iron

WaterWashing of IronOre Sintering Gas Cleaning Residue for Beneficial Reutilization as Secondary Construction Material December 2012 Procedia Environmental Sciences 16:244252

Iron Ore Statistics and Information USGS

Processes for Beneficiation of Iron Ores. satyendra; March 28, 2015; 0 Comments ; Heavy media separation, Iron ore, iron ore beneficiation, Jigging, magnetic separation, washing,; Processes for Beneficiation of Iron Ores Iron is an abundant element in the earths crust averaging from 2 % to 3 % in sedimentary rocks to % in basalt and gabbro.

To form an idea, let us imagine a series of grates placed succes sively at different levels, so that the water, arriving on the highest, where the ore for washing lies, carries off a portion of it, through this first grate upon a second closer in its bars, thence to a third, amp;c., and finally into labyrinths or cis terns of In certain mines of the Hartz, tables called a balais, or

Iron ore is a mineral substance which, when heated in the presence of a reductant, will yield metallic iron (Fe). It almost always consists of iron oxides, the primary forms of which are magnetite (Fe 3 O 4) and hematite (Fe 2 O 3). Iron ore is the source of primary iron for the world''s iron and steel industries.

Iron Ore. Efficiently remove silica and alumina contamination to increase efficiencies in steel production. Our iron ore wet processing plants are proven to successfully deal with silica and alumina contamination in the iron ore, resulting in an increase in the Fe value of the iron ore thereby increasing the efficiency of the steel production process.

Iron Ore HowStuffWorks. Learn how iron ore is mined and eventually refined into things like steel. usually be separated by crushing the raw ore and simply washing away the lighter soil. carbon dioxide and carbon monoxide (releasing lots of heat in the process).

WhatsApp)

WhatsApp)