The Basics of How Ore Processing and Recovery Plants

A 6500 TPD Gold amp; Silver Processing Plant will cost millions of dollars where small mineral pilot plants may cost hundred of thousands and a portable pilot plant may cost only thousands.

WhatsApp)

WhatsApp)

A 6500 TPD Gold amp; Silver Processing Plant will cost millions of dollars where small mineral pilot plants may cost hundred of thousands and a portable pilot plant may cost only thousands.

significant maintenance costs. Without Planning the correct and efficient execution of the work is left to chance. The Planned Maintenance Process is a cycle. Maintenance work is targeted to achieve required asset performance. Its effectiveness is reviewed and improvement

Only where a group of mines operates in a single district are costs comparable and then only with reservations. In general, cost systems are fairly uniform, yet in studying costs of a number of plants it is noticeable that in some cases there is a tendency to omit certain operations which are proper charges against ore dressing and treatment. These should cover the first stage of coarse

The gold grade in the ore is /t, mainly fine particles, and little microparticles. Most of which are concentrated in the range of Natural gold is mainly embedded in pyrite, mainly inclusion gold (%), followed by cracked gold (%). Mine PreDevelopment Site Inspection for a Gold Mine. 2. Processing Plant

Maintenance cost as a percentage of estimated plant replacement value, for example, is usually higher in discrete manufacturing plants than in continuous processing operations. In his book, The Basics of Benchmarking, Robert Damelio points out, A common misconception is that there are lists or databases of universally accepted best practices for a given industry, function, or process.

The popular benchmarking metric of cost/ERV is a valuable tool for setting longterm goals when used correctly in conjunction with targets for plant reliability. Here is how it is calculated. Measures of maintenance cost have contributed to the decline of more than a few reliability professionals careers. From a 35year career in maintenance and reliability,

A small gold mine flowsheet is shown below together with cost data which clearly shows the results that can be obtained when handling a low grade ore by a simple process. There are many commendable features in such a set up and no complicated machines or practices are embodied in this plan

The two gold refining methods most commonly employed to derive pure gold are: the Miller process and the Wohlwill process. The Miller process uses gaseous chlorine to extract impurities when gold is at melting point; impurities separate into a layer on the surface of the molten purified gold.

Objectives of Plant Maintenance 2. Importance of Plant Maintenance 3. Types 4. Schedule 5. Standard Data 6. Some Recent Developments. Objectives of Plant Maintenance: (i) The objective of plant maintenance is to achieve minimum breakdown and to keep the plant in good working condition at the lowest possible cost.

Taking the gold cyanidation plant with processing capacity of 100000 tons and gold grade of g/t as an example, gold CIL process can save the investment cost of 486000 than the CIP process, reduce the capital backlog of 201700, save and recycle capital of 675100 in advance excluding the cost of activated carbon. 2.

building gold processing plant whitehillstree. Jun 13, 2018#183; building gold processing plant building gold processing plant Operating Costs of Gold Processing Plant 911 Metallurgist Mar 25, 2018 A small gold mine flowsheet is shown below together with cost data which clearly shows the results that can be ''obtained when handling a low. Live Chat

(2) Processing cost includes costs associated with the plant, where the ore is processed into gold ( equipment maintenance, plant labor including plant engineers, water treatment, lease, power and utilities, etc.). Expressed as US per tonne processed. (3) Gamp;A cost is comprised of salaries in corporate office, HR, security, environmental

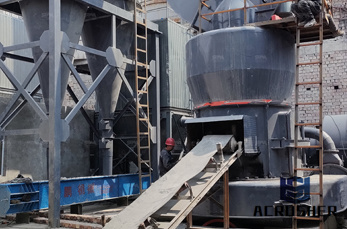

Gold ore . Prominer maintains a team of senior gold processing engineers with expertise and global experience. These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc., to achieve the processing plant of optimal and costefficient process designs.

The Gold Heap Leach Cost Guide provides current costs for todays mining methods and heap leach processing technologies across a wide range of production rates. It surveys the variety of operating conditions worldwide, along with their reserve base, and addresses methods in use to reduce costs and increase the rate of recovery for gold.

Mine cost estimation may be done at many levels. At first it may be a simple back of the envelope estimation using similar operations to benchmark against. Later it may be decided to use an existing mine that the company owns and factor and compare costs against them.

#0183;#32;Data from GFMS shows world gold production costs for the first half of 2009 averaged 457/oz. This average cost is down from 623/ounce in the third quarter of

Estimators, engineers, mine planners, appraisers and purchasing agents have relied on the Mine amp; Mill Equipment Cost Guide for over 20 years. Gathered directly from the source, with manufacturers, dealers and mining companies providing the most current information available.

equitable sharing of operating costs of the refinery (allocation of operating costs) between the participants. A refinery operating cost can be classified under the following heads: Personnel cost. This includes salaries and wages of regular employees, employee benefits, contract maintenance labor, and other contracted services. Maintenance cost.

The Pierina Gold/Silver Mine produced 152,000 ounces of silver last year at a cost of 852/ounce. This means that the once lowest cost gold mine in the world, has become one of the highest cost gold mines in the world. Major mining companies have operating gold mines with total cash cost of gold ranging from 500/ounce to 600/ounce in 2012.

WhatsApp)

WhatsApp)