Coal mill, vertical roller mill operation for process

henke roller mill model 745 ; grains rolling mill manufacturers ; screening machines chile ; jeffrey hammer mill coal 2020

WhatsApp)

WhatsApp)

henke roller mill model 745 ; grains rolling mill manufacturers ; screening machines chile ; jeffrey hammer mill coal 2020

#0183;#32;New vertical roller mill will for coal #173;refinement Inbetriebnme einer Loesche M#252;hle bei der RWE Power AG Commissioning the Loesche mill by RWE Power AG Loesche in D#252;sseldorf received a followup contract for a coal mill, of the type LM D, which is the same type of coal mill already successfully deployed by RWE Power AG in Niederau#223;em.

#0183;#32;Learn about vertical grinding mills and coal pulverizers! We look at all of the vertical grinding mills main components, how it works and some of its design...

Coal grinding mills (CG Group) of the advantages of its vertical roller mill technology. LOESCHE has managed to gain a new customer in Nepal, namely the cement division of the Chaudhary Group based in Kathmandu. This specifies the number of rollers operated in the mill.

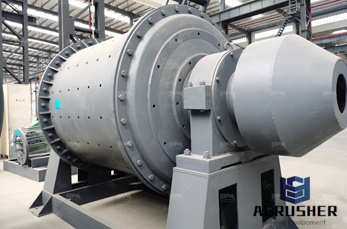

Vertical coal mill, also known as medium speed coal mill. Vertical coal mill drying and pulverizing are combined into one, which can realize grinding and drying, stable system operation, low noise, energy saving and environmental protection.

The MPS mill also grinds, dries, calcines, and classifies gypsum without any problem, all in a single machine, for any fineness requested and considering individual requirements. The MPS vertical roller mill built to last, reliable and energyefficient is the optimum solution when it comes to performing several process steps in one unit.

We have supplied vertical roller mills (VRM) for raw, coal, slag and cement grinding for several decades. The vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials. It is increasingly used as a solution for efficient grinding.

vertical roller mill play an important role in the development of clean coal power. Efficient And Environmentally Friendly Equipment In view of environmental protection, the vertical mill has absorbed advanced technology in the airtightness of the system, which can realize clean power generation in

Since 1906 worldwide market leader in designing, manufacturing and servicing vertical roller mills for the cement, power and industrial minerals industries.

Vertical coal grinding mill integrates crushing, drying, grinding, powder selection and conveying.; It has simple system and compact structure. Vertical coal mill covers an floor area about 50% of the coal ball mill with the same specification.; Coal vertical mills can work in openair environments, greatly reducing the cost of investment. The design of the vertical coal mill system is simple

The coal vertical roller mill has less dust, low noise, high efficiency granular composition, and excellent combustion performance due to its special design and structure Chaeng(Great wall machinery) Vertical Roller Mill has simple process, compact structure, product fineness of 80mR 3%, with steady and average product fineness

Vertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag. It has the features of simple structure and low cost of manufacture and use. Vertical roller mill has many different forms, but it works basically the same.

Our ATOX#174; Coal Mill is a compact vertical roller mill that can grind almost any type of raw coal. The coal mill utilises compression and shear force generated between the large rollers and the rotating table to crush and grind raw coal, removing the need for a separate piece of equipment for crushing.

New vertical roller mill will for coal #173;refinement Inbetriebnme einer Loesche M#252;hle bei der RWE Power AG Commissioning the Loesche mill by RWE Power AG Loesche in D#252;sseldorf received a followup contract for a coal mill, of the type LM D, which is the same type of coal mill already successfully deployed by RWE Power AG in Niederau#223;em.

GRMC coal vertical roller mill produced by CHAENG adopts a special structure design and production technology, and the quality is up to the leading level in China. It is the first choice equipment for grinding raw coal and bituminous coal. 1. The raw coal is screened from the raw coal storage yard and then dropped onto the belt conveyor through the grid screen.

WhatsApp)

WhatsApp)