The use of alunitic kaolin in ceramic tile production

For this purpose, three different recipes were prepared in order to use the concentrated alunitic kaolins in place of the kaolin being used in a ceramic factory.

WhatsApp)

WhatsApp)

For this purpose, three different recipes were prepared in order to use the concentrated alunitic kaolins in place of the kaolin being used in a ceramic factory.

Cations are held between the sheets by relatively weak electrostatic attraction. Kaolinite, in the kaolin group, is by far the most important ceramic clay mineral. Kaolin clays may also contain some feldspar, quartz, and mica but are predominantly kaolinite. Kaolins form by the weathering of granite or feldspar.

#0183;#32;Types of ceramics. People first started making ceramics thousands of years ago (pottery, glass, and brick are among the oldest humaninvented materials), and we''re still designing brand new ceramic materials todaythings like catalytic converters for today''s cars and hightemperature superconductors for tomorrow''s computers. There''s quite a big difference between ageold, general

Kaolin is also known as porcelain clay, or china clay, is used for the production of porcelain, with nonceramic applications including in papermaking and in the

Suspensions of kaolinite and ceramic grade kaolin in sodium hexametaphosphate solutions at different concentrations were prepared and kept at constant temperature for 4 h: the solutions obtained after centrifugation and filtration were analysed using a ICP technique to determine the concentration of significant cations.

role of kaolin in making a ceramic. Porcelain Wikipedia, the free encyclopedia. The particle size of Kaolin plays an important role in fillers and coatings, as larger Ceramics Kaolin has a wide range of application is the ceramic industry, and is These are essentially the same qualities that make kaolin . READ MORE. China Kaolin Clay For Ceramic, Kaolin Clay For Ceramic . More related

Well, in a short sentence, ceramic is any solid sculpted body made of clay that has lost its plasticity after being fired. Ceramics are corrosionresistant, hard, and brittle objects. Once the clay is fired, it melts a little, releases some gases, loses the retained water, and forms very sturdy bonds amongst the particles. This is called ceramic.

Origin of Kaolin Clay. Kaolin clay is included in the group of hydrous aluminum stones kyanite and dumortierite are aluminum silicate. Aluminum is also found in the healing stones sapphire, amethyst, heliotrope (bloodstone), ruby, anyolite, emerald, idocrase, rhodonite, tiger iron, green tourmaline, alexandrite and kaolin mineral group include other common clay

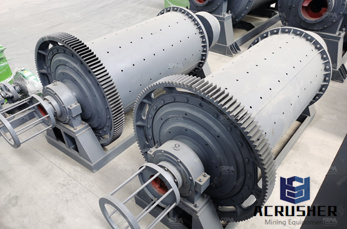

role of kaolin in making a ore. 250tph river stone crushing line in Chile. 200tph granite crushing line in Cameroon. HGT gyratory crusher has many incomparable advantages such as high crushing efficiency, low production cost and simple maintenance method, which can satisfy the requirements about high efficiency and coarse crushing.

Kaolin is used in many industries other than ceramics, in fact the ceramics industry uses only a small amount of the total kaolin produced. Kaolin companies tend to be billiondollar operations and kaolin is used in everything from paper to cosmetics, paint to agricultural products.

Usually a glassceramic is not fully crystalline; typically the microstructure is 50vol% to 95vol%.. diopside nor the presence of a second crystalline phase played a major role in determining.. making dense ceramic materials... (KLiFeAl(AlSi3)O10(F,OH)2) were not found in the glassceramic sintered from the kaolin. Read more

Calcined kaolin is also available, it is got by firing kaolin at high temperature to remove the crystal water present in it, it is mainly used in ceramic industry. Kaolin Clay Benefits amp; Uses Due to its mild nature it is perfect for using it on all types of skin and since it dries up firmly on the skin, it

Kaolin | clay | Britannica

Kaolin is used extensively in the ceramic industry, where its high fusion temperature and white burning characteristics makes it particularly suitable for the manufacture of

When kaolin is mixed with water in the range of 20 to 35 percent, it becomes plastic (, it can be molded under pressure), and the shape is retained after the pressure is removed. With larger percentages of water, the kaolin forms a slurry, or watery suspension.

The artifacts belonging to the ceramic heritage are mostly based on all clay types used by humans over the ages, because the sources of clays were easily available and people were interested to produce ceramics and pottery. This is the reason why the conservation of cultural heritage is of great concern. Ceramics (Greek Keramion) is a material obtained by shaping and firing clay.

This paper examines the role of iron in mullite nucleation and growth from kaolins. We chose two typical raw kaolins containing a reduced impurity level and characterized by very different degrees of crystallinity of the kaolinite phase.

WhatsApp)

WhatsApp)